Industrial robot application programming

Industrial robot application programming

Millions of industrial robots' programs generated using AUTOMAPPPS!

AUTOMAPPPS software has proven as a solution for time and cost saving industrial robot programming. For single- and multi-robot cells with and without line-tracking. So millions of robot programs that has been generated by AUTOMAPPPS are executed each year. And when we say “millions per year”, we exclude ten million programs that were automatically planned for bin-picking or other “short jobs”.

Industrial robot programming at it's best

AUTOMAPPPS stands for industrial robot programming as it's best. Furthermore it is applicable for almost all major brands of industrial robots. Some selected robot applications and processes ideally supported by AUTOMAPPPS process models, simulation and programming are:

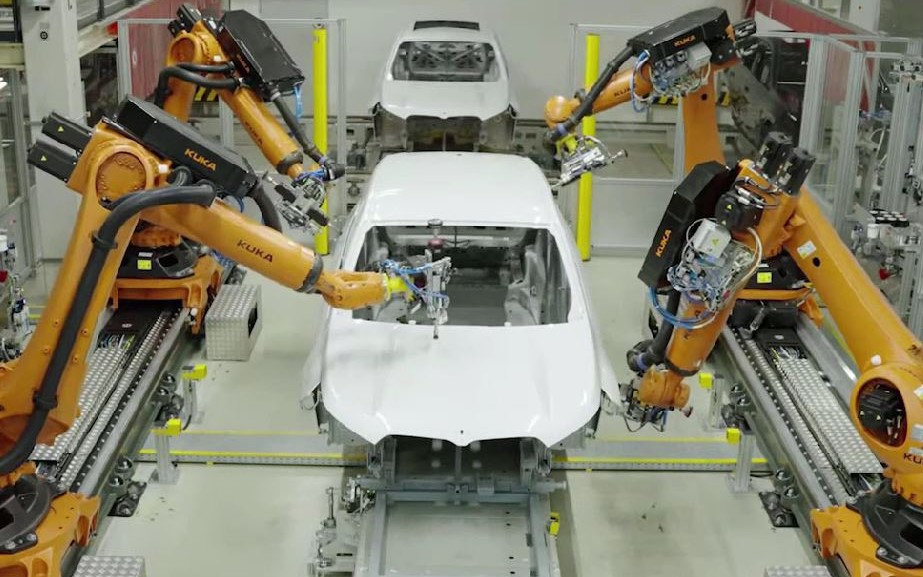

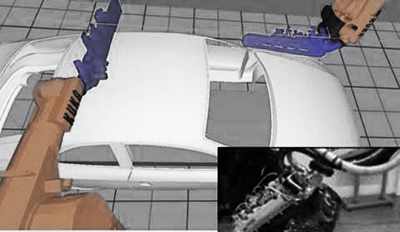

Robotic Grinding/Sanding

Example: car-body grinding:

- Optimized, validated layout

- Minimized required space and cycle time

- Minimized time and cost for robot offline programming

- Reduced test-runs, non-productive time and risks

- Cells between 1 and more than 10 robots

- Cells with and without rails, conveyors and rotatory axes

- Jobs ranging from seconds to minutes in execution time

Image courtesy of ASIS GmbH, Landshut.

Multi-Tool robotic grinding

Example: grinding for food industry:

- Fast programming for twin-headed sanding tool attached

- High surface quality for anti-bactiera properties

- Reduced test-runs, non-productive time and risks

- Compact cell with large parts and robot with rotation axis

- Jobs of very long execution time

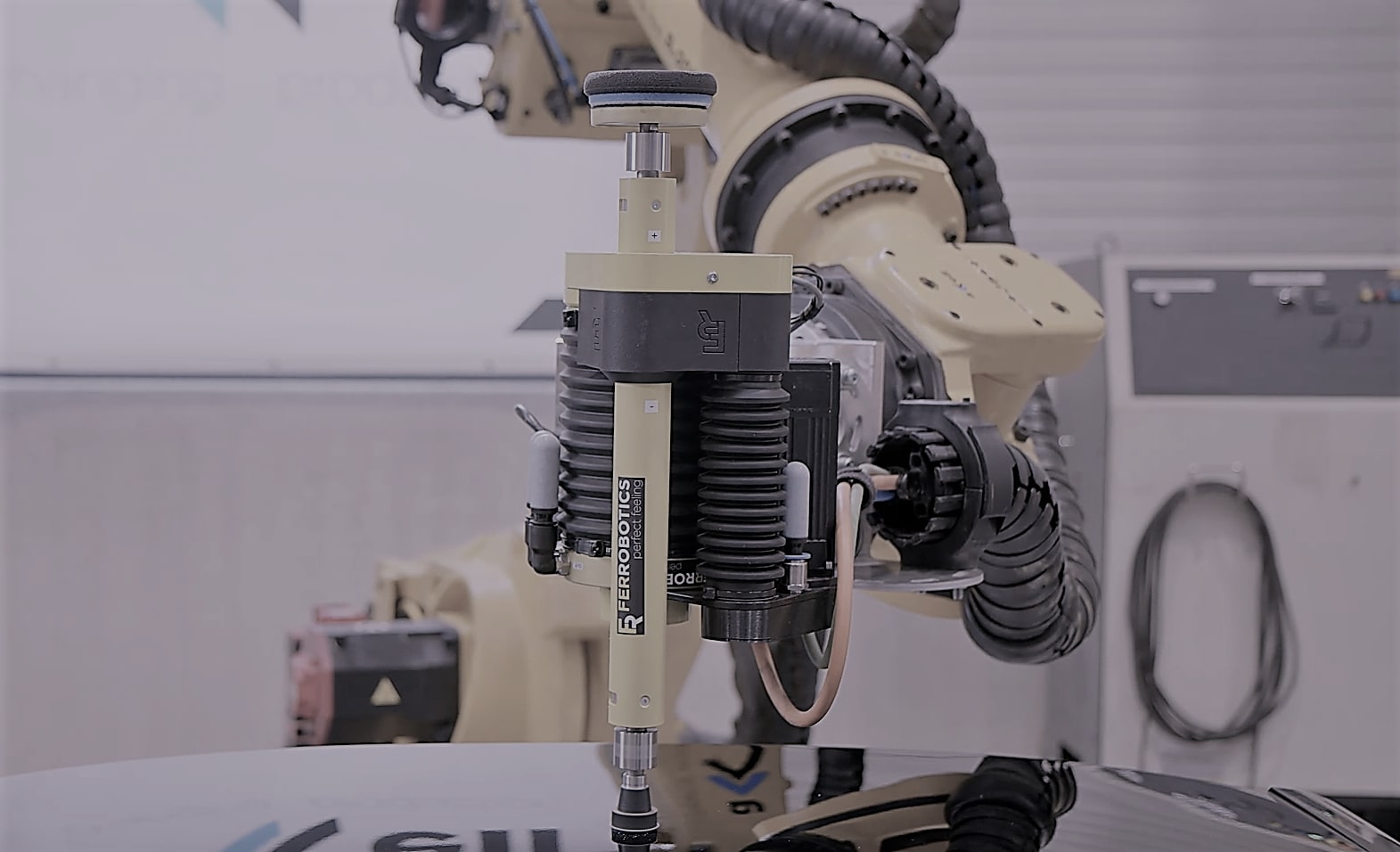

Robotic E-coat Repair

Example: repairing detected surface defects

- Application of real time robotics

- Robots grind defects

- Input: defects detected by vision system

- 100% automated task planning

- Programming robots in seconds

- Multi-Robot system

Image courtesy of ATENSOR Engineering and Technology Systems GmbH, Austria

Robotic Belt Grinding

Example: grinding free-form parts

- Part in Hand

- Improved grinding quality

- Grinding simulation

- Reduced testing and non-productive state

- Minimized time and cost for programming and optimizing

- Reduced space required

More details after approval.

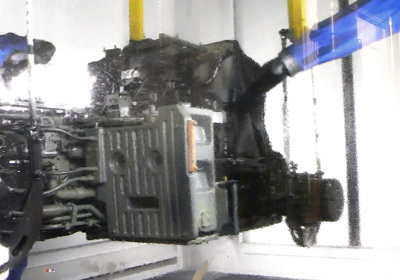

Cleaning Robots

Example: 100% cleaning of car-bodies (prior to painting)

- Improved dust removal

- WYSIWYG simulation of cleaning

- Reduced testing and non-productive state

- Minimized time and cost for programming and optimizing

- Cells with 1 to 6 robots and auxiliary axes

- Reduced space required, reduced cost for hardware

- Minimal cycle time

Image: Robot offline programming car body cleaning and validation tests together with WANDRES and a large German car manufacturer

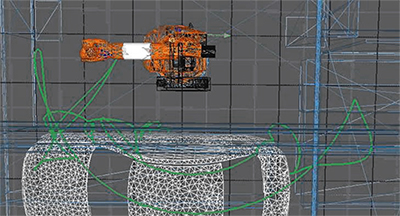

3D Measurement - Visual CMM – Visual Metrology

Example: 3D measurement of work-pieces

- No robot experts required

- Minimized time and cost for programming

- Reduced trials and non-productive state

- Single-robot measuring cells and multi-robot systems

- Robots with and without auxiliary axes

- Minimized execution time

Image courtesy of AICON 3D Systems GmbH

Inspection

Example: 100% paint inspection

- Improving coverage and result of automation

- Optimized cycle time

- Automatic multi-robot collision avoidance - active

- Minimized time and cost for robot offline programming

- Single-robot measuring cells and multi-robot systems

- Allows for intuitive immersion into the process

Image courtesy of Micro-Epsillon Messtechnik GmbH &CoKG

Quality Control

Example: robotic control of product features

- Simple operation and robot instruction

- Automatic compensation of very large pose deviations

- Very fast instruction of the robot

- Collision free robot motions in narrow environment - automatically

- Improved OEE (overall equipment efficiency...)

Image courtesy of: confidential.

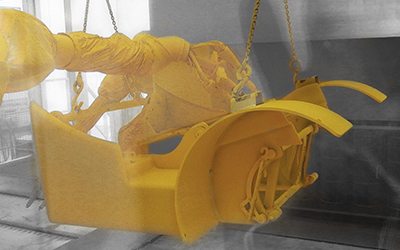

Powder Coating

Example: Robotic Powder Coating OLP

- Powder-coating and painting

- Simple and fast robot offline programming

- Simulation for reduced test-runs and optimization

- Support for line tracking

- Usually 1-2 robots

- Support for external axes

Image courtesy of Jungheinrich Moosburg AG & Co. KG, Germany

Painting

Example: Robotic Painting Offline Programming

- Simple and fast robot programming

- Up to 10,000 variants and more

- Simulation for reduced test-runs and optimization

- Support for line tracking

- Usually 1-2 robots

- Support for external axes

- Programming by shop-floor staff

Robotic Marking

Example: marking detected surface defects

- Programming robots in seconds

- Robots react on defects

- Real-time properties

- Several million programs per year

- Higher product quality

- 100,000€ savings of HW costs by software

- Savings of space in the production line

- Stop and go or conveyor tracking

- 2 or 4 robotsRemote or contact-based

High-Pressure Cleaning

Example: Robotic Cleaning

- Simple and fast robot programming

- Commonly large or complex parts

- Support for line tracking and rotation tables

- Usually 1-2 robots

- Support for external axes

- Programming by shop-floor staff

Bin-Picking

Example: high-speed random bin picking of metal parts

- Robust - frequently proven on shop-floor

- Reduced cycle time through optimal motions

- Reduced time to market and development cost

- Higher re-use: for virtually all robot manufacturers and sensors

- Fast setup and remote optimization

- Fast adaptation to different parts to handle

Image courtesy of bsAutomatisierung GmbH, Germany

Vision-based robotic sanding

Example: windown grinding

- Vision-based programming of robots

- Sensory adaption to new windows

- Lotsize-1

- Tool-path and motion planning

- Planning of robot and external axes

Image courtesy of ADLER-Werk Lackfabrik Johann Berghofer GmbH & Co KG, Austria

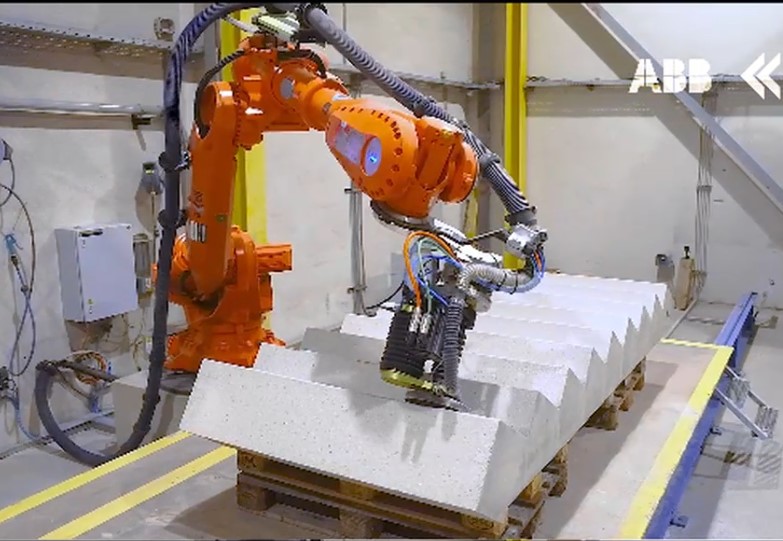

Robotic concrete grinding - with vision

Example: robots in construction industry- 3D camera based

- Fast and easy programming of grinding

- Camera-based

- Compensating shape deviations

- Compensating very large pose deviations

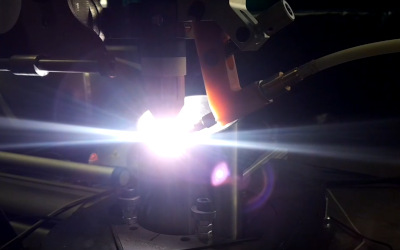

Vision-based deburring

Example: grinding welding seam

- Fast and easy programming of burr-following

- only grind where and as much as needed

- reducung time and tool wear

Robotic deburring

Example: robotic deburring

- Fast and easy programming of burr-following

- Motion planning in strongly structured parts

- Planning of robot and external axes

Image of robotic deburring cell courtesy of BOLL Automation GmbH, Germany

Cutting / Wood cutting

Example: robot based cutting of wood structures

- Lot size 1, automatically programmed

- CAM interface

- Robot and auxiliary axes

- Very large structures

- Collision free, precise motion in narrow environments

- Fully integrated in external GUI

More details after approval

Shape correction

Example: industrial robots cutting of shape deviation

- Lot size 1, automatically programmed

- Input from 3D vision sensors

- Corrects 3D shape of parts

- Different milling/cutting tools in hand

More details after approval

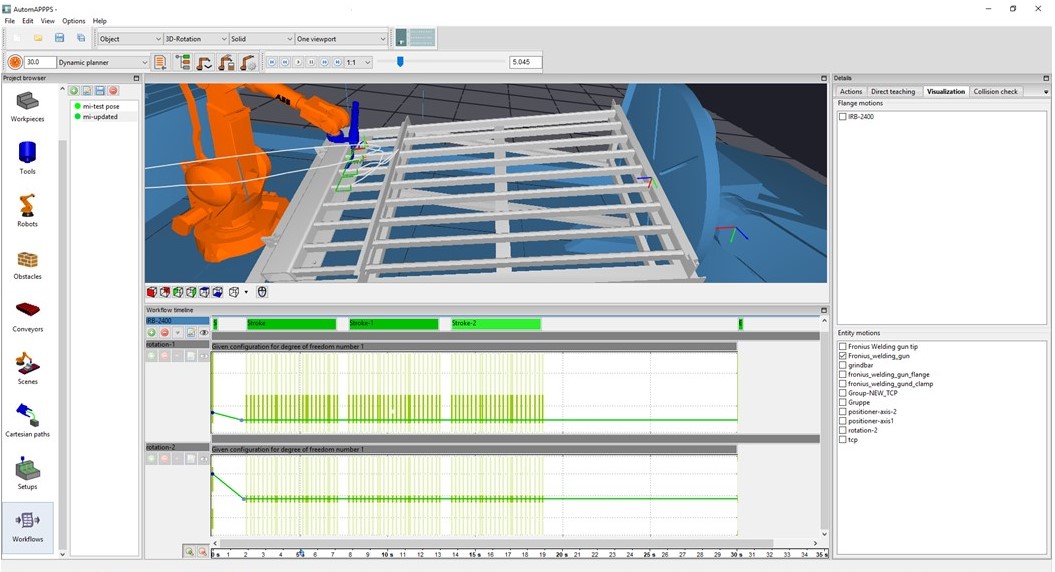

Welding

Example: Welding using 2 DOF rotation table

- Intuitive CAD-based programming

- Reduced cycle time through optimal motions

- Intutive weld-definition using CAD featurers

- Collision free motions in narrow structures

Welding

Example: Welding part-in-hand

- Intuitive CAD-based programming

- Reduced cycle time through optimal motions

- Intutive weld-definition using CAD featurers

- Collision free motions in narrow structures

Waterjet-cutting

Example: Watercutting, 2 robots

- Intuitive CAD-based programming

- Reduced cycle time through optimal motions

- Intutive weld-definition using CAD featurers

- 2 robots collision avoidance

Image courtesy of UniPro LTD

AGV + mobile manipulation

Example: industrial robots sanding boats/moulds

- Planning robot motion and AGV poses

- Very large parts and narrow corridors reach

- Special feature support for faster path definition

- Parts placed at different poses

Image courtesy of EuropeTechnologies

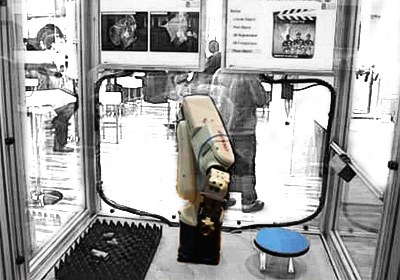

Programming Cobots

Example: programming a TechMan robot/cobot offline

- Submillimeter accuracy required

- More than 100 points

- Reflective surface

- Fast and easy programming with CAD2path replaces tedious teaching which is hard on the eyes

- Easy programming

Image courtesy of ATJ Automotive GmbH

Furthermore many more different processes have been programmed and simulated with AUTOMAPPPS robot offline programming software and fully automatic programming software. It has been successfully used with 20 different robot brands and in combination with a dozen different sensor systems.

Even narrow spaces, line-tracking in narrow cells in-between chains or skids or inside car-bodies, or multiple robots in the same working range are supported. As a result all challenges in industrial robot programming have been mastered without common iterations or extensive testing upfront.

Your process has not been listed? Send an email and find out what we can do for you.