Automatic, vision-based Paint-Repair / Surface Repair with Robots:

AUTOMAPPPS - the most deployed and trusted paint-repair software

We are the pioneers in robotized paint-repair and offer proven software in a bundle with years of shop-floor experience in paint-repair / spot-repair with robots - for superior quality and for more complete surfaces.

With almost 15 years in paint repair and more than a decade in scan-sand-polish, AUTOMAPPPS software is millions of programs ahead.

Trusted by leading system integrators.

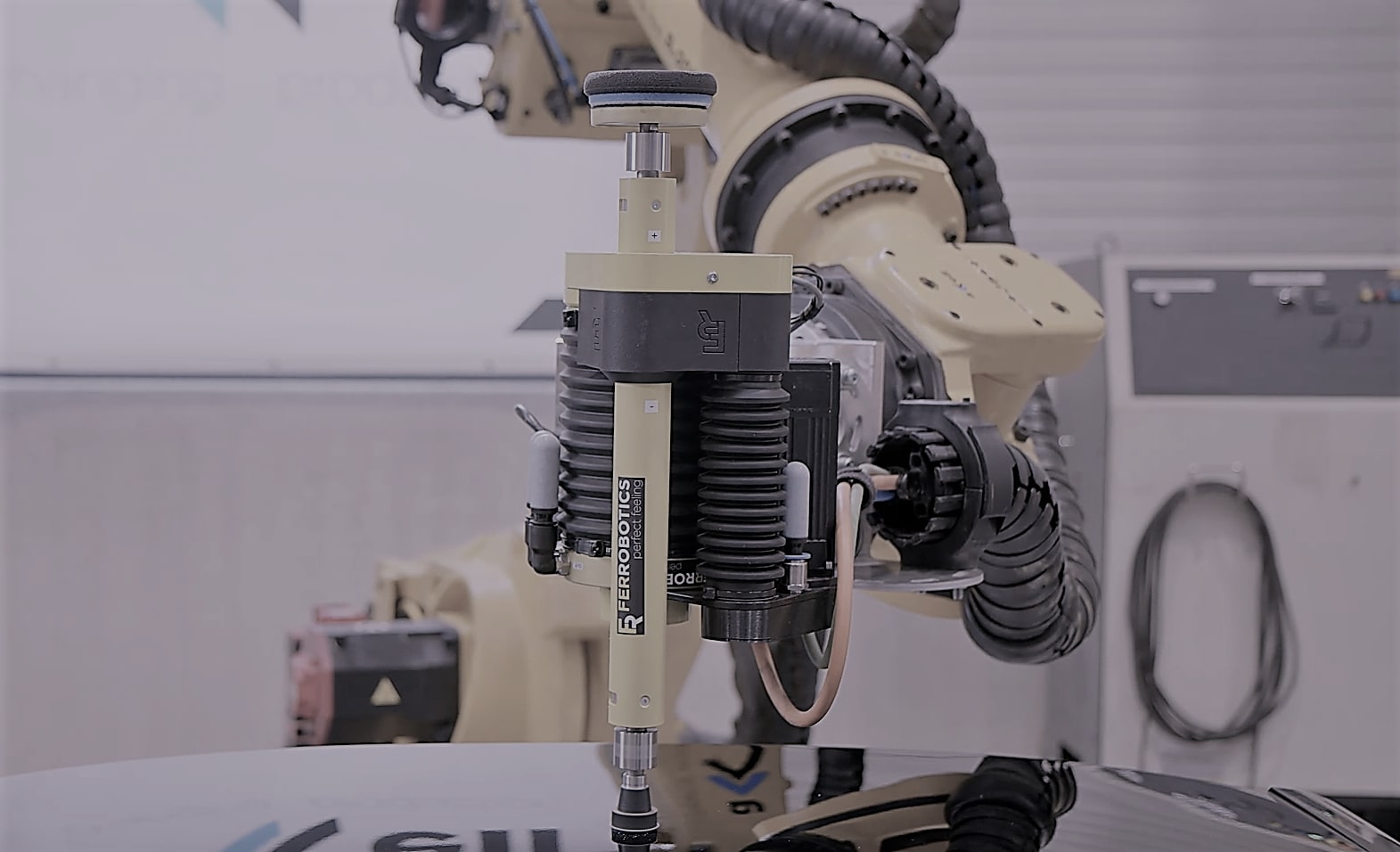

Robotic paint repair prorammed by AUTOMAPPPS enabling 2 KUKA robots and Ferrobotcs AOK paint-repair hardware. Image courtesy of ASIS GmbH Germany

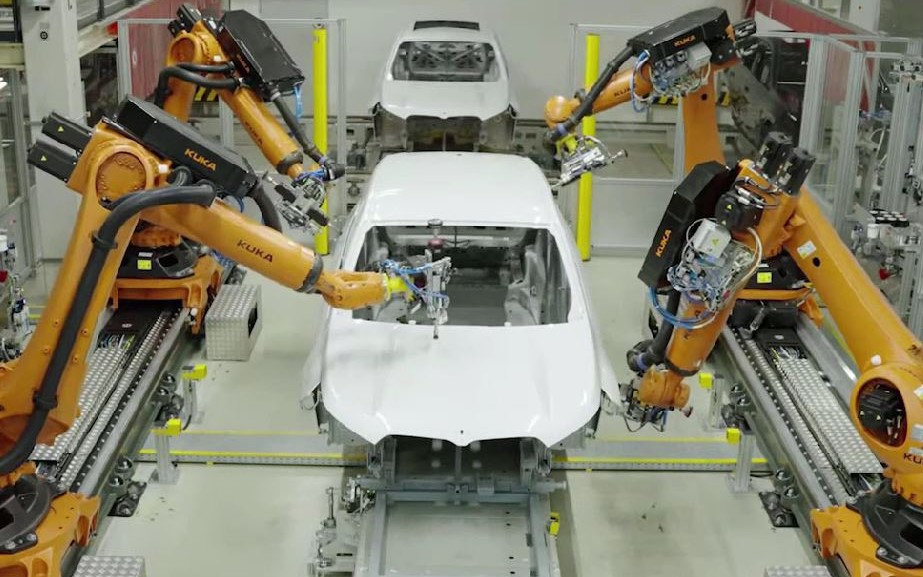

Robotic paint repair prorammed by AUTOMAPPPS enabling 4 KUKA robots and 3M paint-repair hardware.

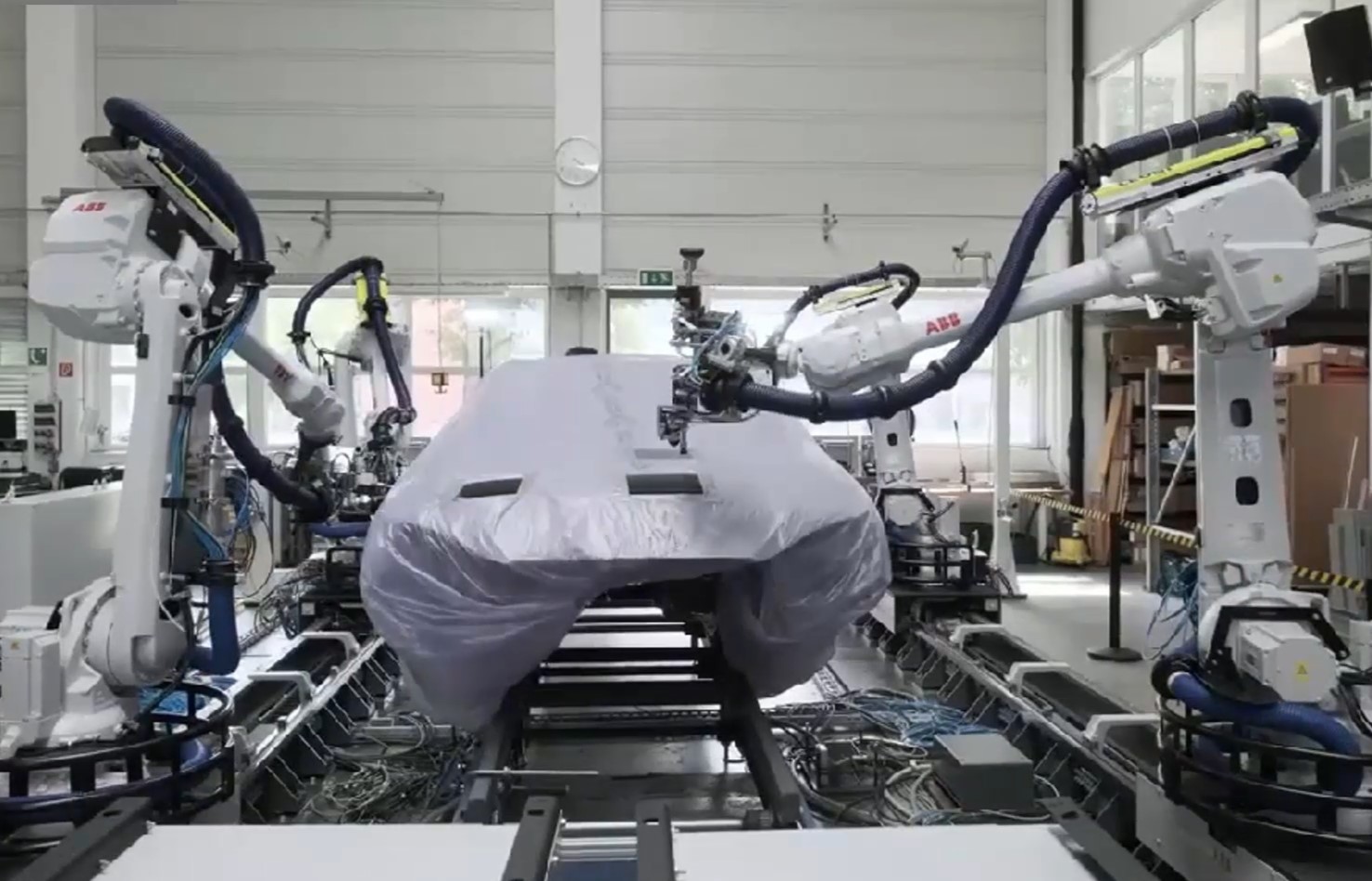

Robotic paint repair prorammed by AUTOMAPPPS enabling 4 ABB robots and 3M paint-repair hardware. Image courtesy of ASIS GmbH Germany

ADVANTAGES:

Superior quality

- Factory proven planning of paint-repair

- Years of experience in optimal quality

- Optimized in dozens and dozens of robots deployed

Higher coverage / better ROI

- Automat. treatment of complex shapes

- Treats defects near and on edges

Wide applicability

- Deployed with different active tools

- Different inspection sensors supported

- Supporting different robot producers

- Proven on metal and plastic

- Paint, primer and CDP coating

Low risk

- Most deployed paint repair software world-wide

- Many years + millions of programs ahead

- 10Y + process experience

Faster, safer ramp-up:

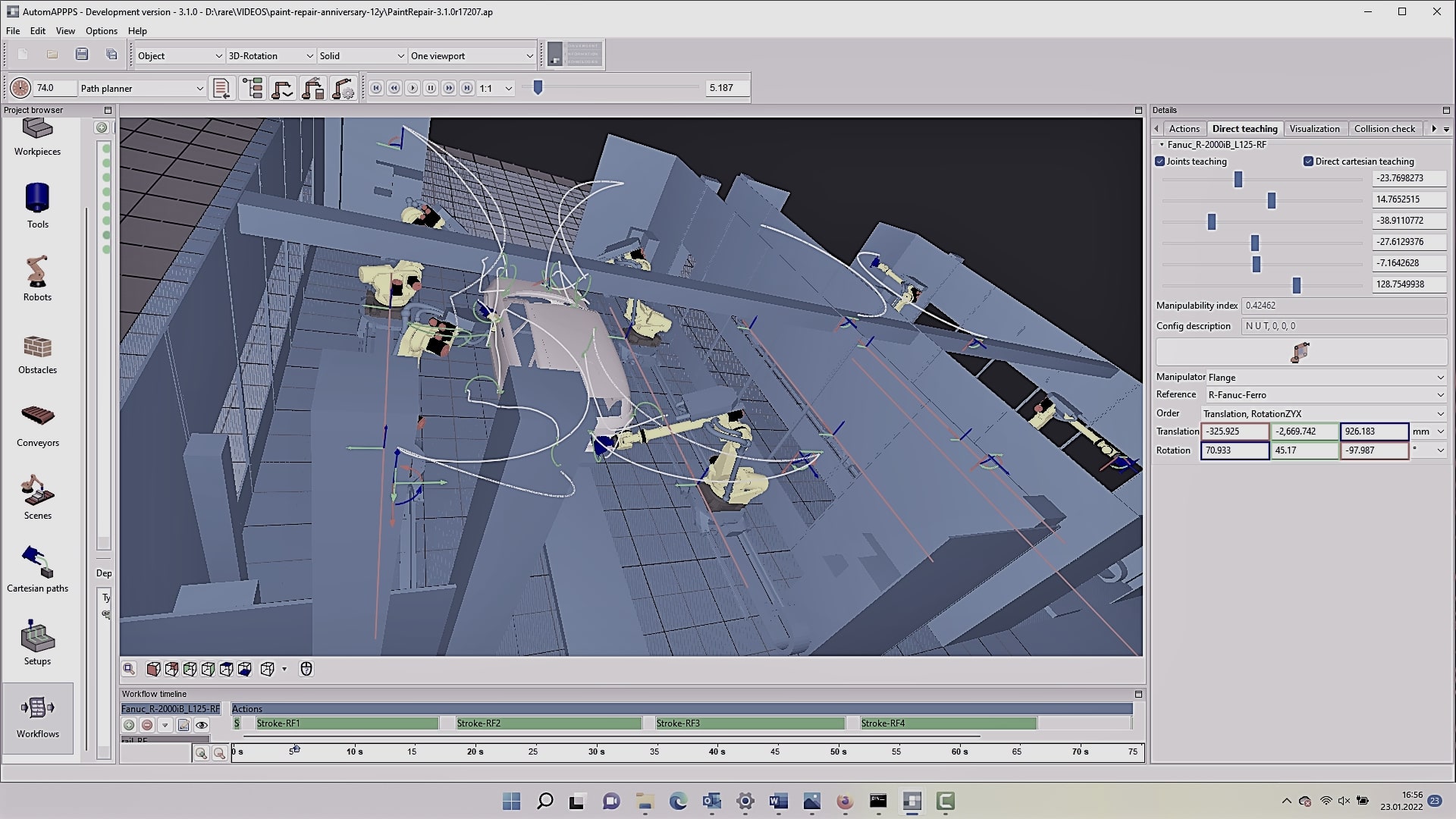

- Full tool chain for online and offline

- Improved during many deployments

- Simulation support

- Visualization support

- Analyis and remote optimization support

- Plus years more experience

- Multi-robot and multi-cell

- For car-bodies and components

Cost effective:

- Higher OOE, faster time to operation

- Less trials and test-runs

- Higher efficiency

- Fast repair

Smart / self improving option. Learning:

- best recipe for different defects

- best recipe group for defect porperties

- for better motions and sequences

- for faster planning

Scan-Sand-Polish cells for repair of plastic components. Image courtesy of ACCEL GmbH Austria

More than a decade paint-repair planning for multi-robot cells

The very beginning - e-coat repair more than a decade ago. Before HW producer even thought of providing specialized paint repair tools.

APPROACH:

- Multi-stage and multi-robot planning

- Reactive paint-repair planning

- Scheduling

- Fast robot motion planning

- Automated multi-robot collision avoidance

- Automated robot code generation

- Realtime robotics capable

Truly superior paint quality / repair quality.

SUPPORTED PROCESSES

- sanding (wet)

- sanding (dry)

- polishing

- pre-treatment

- marking

Download the flyer for reactive online robot programming.

AUTOMAPPPS-spot repair has proven for years and in many deployments of robots in and for paint-repair. With more than a decade of deployments in factories. This longstanding head-start can be felt immidiately observing robots commaned by AUTOMAPPPS software in action. With the experience from more installations and repair-jobs generated than anyone else, our grinding/polishing experts can help you optimize your surface-repair application to the next level.

With our tool-chain and support gadgets/tools, developped and optimized over years of in-factory use, spot repair / paint-repair projects with robots become faster to realize and best-practice.